1 shows a schematic of the corrosion process on iron along with the possible half cell reactions depending on the type of environment 12.

Galvanized of batch annealed steel sheet.

Since then several improvements have been made in the process which allows several types of steels to be processed by this method.

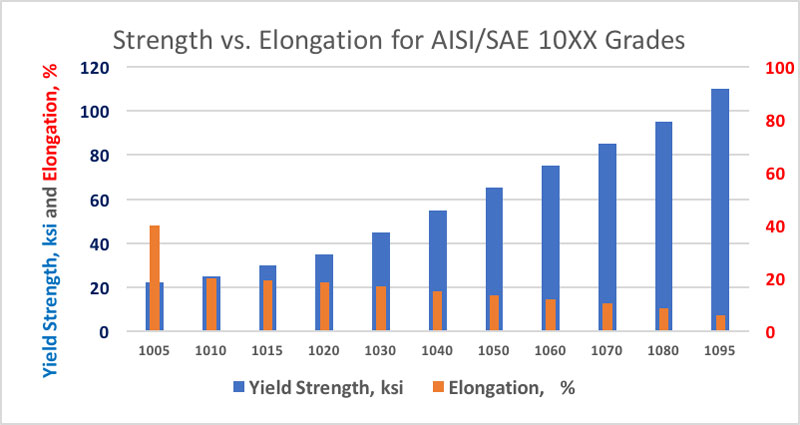

This produces high strength but low elongation.

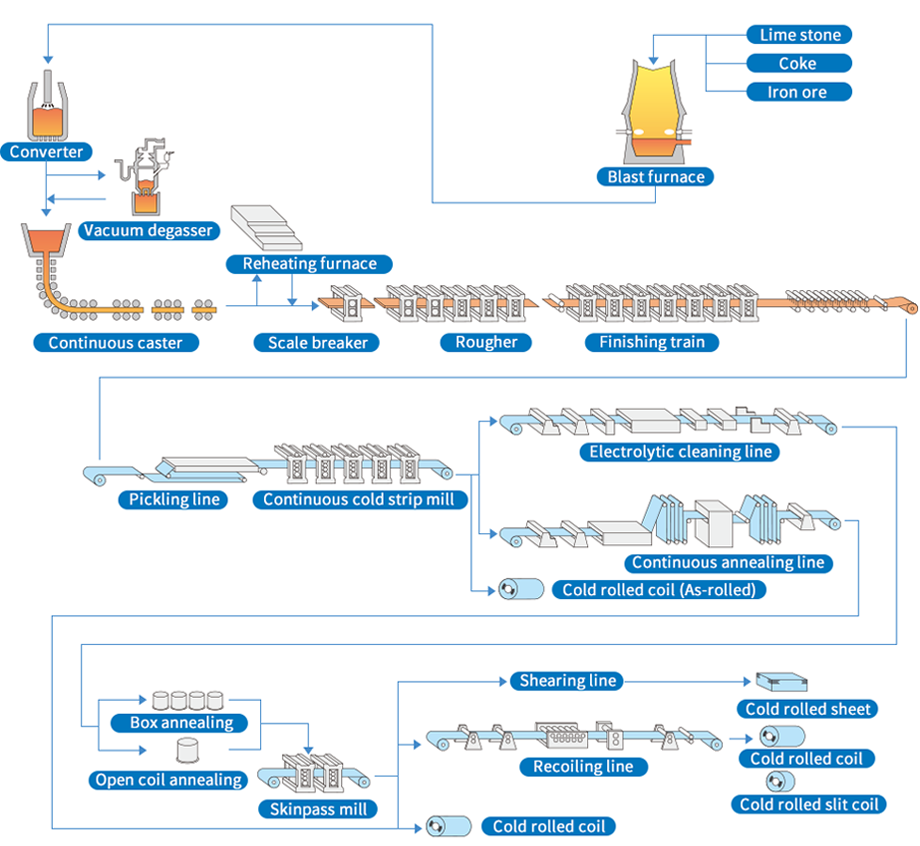

Cold roll sheet producers were building 5 stand sheet cold reduction mills many added batch annealing facilities in order to process the additional cold reduction throughput.

Galvannealed or galvanneal galvannealed steel is the result from the processes of galvanizing followed by annealing of sheet steel.

Galvannealed steel is a matte uniform grey color which can be easily painted.

In comparison to galvanized steel the coating is harder and more brittle.

Galvanized sheet manufacturer supplier in china offering black annealed cold rolled with competitive price black batch annealed cold rolled coil ppgi ppgl sheet price prime quality prepainted galvanized color coated steel sheet and so on.

This was due to the higher cooling rate when compared to batch annealing.

Cold reduction or work hardening makes steel grain structure small and elongated.

Annealing recrystallizes the grain structure restoring ductility so the material can adequately.

52 aise steel technology november december 2002 in the mid 1960s and early 1970s as u s.

Both steels are passed through a hot dip coating process for rust prevention.

Often these facilities consisted of a 4 stack per operating base configu.

Rite precipitated as cementite during cooling by batch annealing it remained in supersaturation after cooling by continuous annealing.

Galvannealed steel goes through and additional annealing process which vastly improves the formability and paint adhesion.

Steels galvanized steels and aluminum alloys are industrially important metals that are produced in large quantities.

Of these materials the corrosion protection of steel is most challenging even if iron is more noble than zinc or aluminum 2 fig.

As a result continuously annealed sheets were hard and exhibited aging properties.

Continuous annealing of cold rolled steel was first introduced by the armco steel corporation in the year 1936 as a process step in the production of hot dip galvanized steel.

Annealing of cold rolled steel involves a time and temperature controlled thermomechanical process used predominantly to make steel soft again after cold reduction.

A coil to coil process steel sheets from 0 010 to 1 70 inches 0 25 mm to 4 30 mm thick and up to 72 inches 1 830 mm wide is passed as a continuous ribbon through cleaning baths and molten zinc at speeds up to 600 feet per minute.